MYSTIC NEXT

Sustainability

A word on the impact of our products.

Mystic Next

We want to be honest. Even with the amount of time we spend outside and in the water, producing gear for the sports we love may not always be the best for sustainability. But driving positive change is necessary, and something we are working towards. That’s why transparency is essential. It allows us to openly communicate our progress, challenges, and commitments, while actively engaging our network and industry to do the same.

To do what we love, we need gear, but we also urgently need healthy waters, unspoiled coastlines, and a sustainable planet. We need to optimize the impact our products have on communities engaged in their manufacturing. It’s why we’re committed to minimizing our products' environmental and social footprint. We continuously research and explore new materials and fibers for our collections, while using the most sustainable manufacturing practices available to us.

Durability forms the foundation of our design philosophy. We craft products that offer long lives and innovate product features based on this standard. Our research so far shows our harnesses have a significantly low warranty rate. This means a low failure rate, ensuring our harnesses are out there doing what they’re supposed to, for as long as they can. Through comprehensive facility testing, we ensure our spreaderbars meet the highest standards of strength and fatigue resistance.

Clothing care guide

We craft every garment with precision and durability in mind, built to last through all your adventures. But the key to keeping your gear in top shape is proper care.

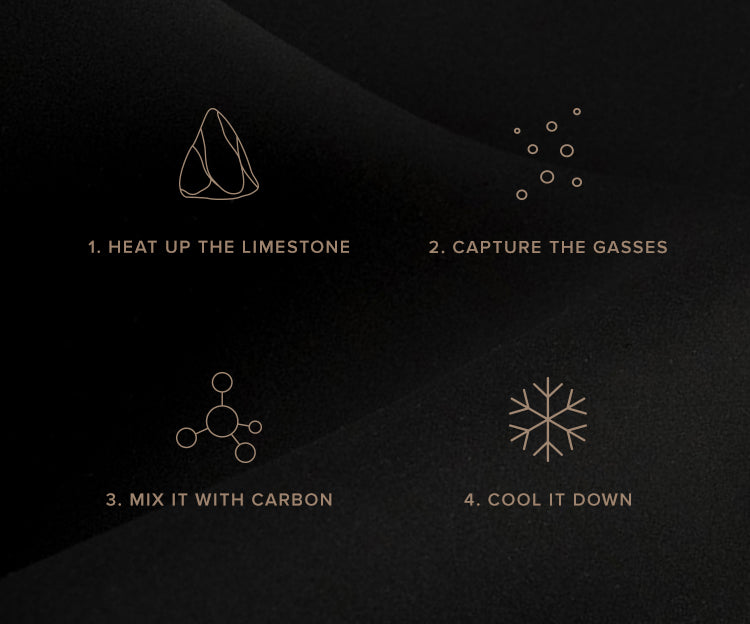

How is Yamamoto rubber made?

Yamamoto limestone is from Japan, excavated in Osaka’s quarries, and processed on-site. Limestone neoprene gets produced in sheets of rubber. Because of the high demand for the outer smooth layers of these sheets for triathlon wetsuits, we’ve decided to go for the middle layers, reducing some neoprene waste. Waste energy is used to power local eel farms, making the most out of the resources. It still takes a lot of energy to process limestone for wetsuit production, so we’re discovering additional and better neoprene alternatives to add to our lineup.

General Tips

Looking after your clothes helps them last longer and reduces your impact on the environment. A little extra effort goes a long way, so here are some simple tips to get started.

Wash less

Wash your clothes less frequently. It’s simple—washing wears out fabrics. If it’s not dirty, let it air out and save the wash for another time.

Care labels

Check the care labels to identify the type of fabric and follow the recommended washing instructions for best results.

General wash guidelines

Sort by color and fabric, turn everything inside out, and keep those delicate items separate.

Dry cleaning

Many clothes labeled as ‘dry clean only’ can actually be washed at home on a gentle cycle, saving you time and effort. If you do need to dry clean, look for services that use eco-friendlier methods to reduce the impact on both your clothes and the environment.

Detergents

Standard detergents often contain chemicals that aren’t great for your clothes or the environment. Fortunately, there are now plenty of effective, eco-friendly options made from biodegradable, plant-based ingredients.

Drying

Air drying is a simple way to keep your clothes in better shape for longer while also saving energy. Whenever possible, hang your garments outside or on a drying rack, turning bright or dark items inside out to prevent fading. Some items, like insulated or waterproof fabrics, actually benefit from a low-heat tumble dry to maintain their performance, so be sure to check the labels and follow their care instructions.

Insulated garments

For insulated gear, use a down-specific detergent to protect the natural oils that keep the insulation performing at its best. Wash on a gentle cycle with cold water, and always air dry or tumble dry on low with dryer balls, tennis balls, or a heavy towel. This way, you keep the insulation fluffy and evenly distributed, just the way you want it.

Repair

A small repair can extend the life of your gear, from garments to wetsuits. Simple fixes like patching tears, fixing zippers, or re-stitching seams prevent further damage, save you from replacements, and reduce waste.

Fabric Care

Different fabrics require different care. Here’s an overview of our main fabrics, and how to care for each of them.

Cotton

Wash cotton garments in cool-to-warm water with a gentle detergent, and line dry when you can to keep them in top shape. If you need to use a dryer, stick to a low-heat setting, and always check the care label for any specific instructions.

(Recycled) polyester

Polyester is pretty low-maintenance and easy to care for. Machine wash it in warm water on the permanent press setting with a mild detergent, and line dry if you can. If you’re using a dryer, go for a low heat setting and take it out promptly to avoid wrinkles. For stubborn stains, a little dishwashing liquid on the spot should do the trick—just rub gently and rinse thoroughly.

(Recycled) nylon

Nylon is durable and easy to maintain. Machine wash it in cool-to-warm water with a mild detergent, and line dry or tumble dry on low heat to keep it looking its best. Avoid high heat, which can damage the fibers.